Reliable performance, high productivity and superior part transfer is just the beginning. The Vicon Coil Line is backed by our exclusive commitment to provide you with nationwide one-call service, training and support for as long as you own your machine.

ViSoft Software is menu-driven, user-friendly and can be set to SMACNA standards or customized to your shop standards. Continually updated and supported by Vicon’s experienced team of programming engineers, ViSoft ensures enhanced productivity and superb part accuracy.

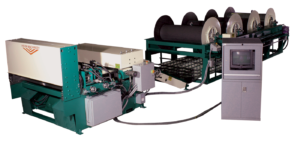

- Vicon Coil Handling System

The VICON Coil Cradle System is the fastest and easiest coil loading process in the industry. Coils are spooled on VICON’s

patented Coil Drum Assemblies (US Patent #7,673,915). The coil spool is easily inserted into the coil material with the use of

a forklift in a matter of minutes. Coils are then loaded into the coil cradles with the use of a forklift or crane. The entire process

can be completed by a single individual.• * Number of Stations: 1 – 6

• * Maximum Coil Weight: 12,000 lbs per station

• * Maximum Coil Width: 60”

• * Maximum Coil O.D.: 42”

• Coil I.D.: 20”

* Optional capacities available upon request - VICON Duct-Line Express

The Duct-Line Express front-end is the core of the VICON duct fabrication system. Additional VICON coil line components are

modular and can be easily added to complete the Full Coil Line.• 16-30 gauge mild steel capacity

• * 12,000 lbs maximum coil capacity (with coil drive)

• * Coil widths from 48”- 60” standard

• * Number of Stations: 1-6

• Quick-change coil spools (US Patent #7,673,915)

• Individual Hydraulic coil drive motors

• Powered in-feed guide ramp with hand wheel for change in coil widths

* Optional capacities available upon request - VICON Shear & Bend System with Optional Cleat Forming

The modular VICON Shear & Bend Front End System can easily be expanded to a Full Coil Line.

• 16-30 gauge mild steel capacity

• 12,000 lbs maximum coil capacity (with coil drive)

• Coil widths from 48”- 60” standard

• Number of Stations: 1-6

• Quick-change coil spools (US Patent #7,673,915)

• Individual Hydraulic coil drive motors

• Powered in-feed guide ramp with hand wheel for change in coil widths

• Optional capacities available upon request - VICON Lockseam System and Transfer / Feed Conveyor System

The Superior Design of the VICON Lockseam System is the most user-friendly and reliable system for automatically forming Pittsburgh and Snap-Lock seams. VICON’s “Accessible Concept” creates a system free of overhead devices, eliminating any possibility of miss-feeds or jams. The “open top” allows feeding of oversize blanks to the TDX, liner and brake systems.

• Heavy duty roll form heads

• 120” maximum and 14” minimum duct stretch-out

• 138” maximum material stretch-out on 4 piece duct

• 18-26 gauge mild steel capacity for Pittsburgh

• 20-28 gauge mild steel capacity for Snaplock

• Lighter and heavier capacities available upon request - VICON Dual Head Cleat Edge Former

The VICON Dual Head Cleat Edge Former rollforms a 7/16” cleat edge on both ends of the duct after the Male and Female lockseam has been rollformed.

• 18–26 gauge mild steel capacity with no

adjustments required

• 7/16” cleat edge with minimum cleat length of 4”

• 3 HP motor coupled to a heavy duty oil bath gear reducer

• 8 Station heavy duty conventional roll form heads

• Heavy duty roller chain drive (no belts)

• Robust 1” diameter stress proof roller spindles - VICON Dual Head TDX Rollformer

The VICON TDX Dual Head Rollformer is designed to produce your preference of either T-25a or T-25b SMACNA approved

transverse flange connector.• 18-26 gauge mild steel capacity with no

adjustments required when changing metal thickness

• 10 HP motor coupled to a heavy duty oil bath gear reducer

• Heavy duty roller chain drive (no belts)

• Rugged 1-1/4” diameter stress proof roller spindles

• 16 gauge mild steel capacity available upon request - VICON Automatic Duct Liner Application System

The VICON Automatic Duct Liner Application System uncoils and shears the duct liner, applies liner adhesive to the sheet metal and automatically locates and pins the liner to the sheet metal. No tooling or blade changes required on shearing process.

• Automatic adhesive extrusion application system

• Multi-speed drive for optimum pinning speed or bypass of unlined duct

• Designed to apply 44”, 47”, 48”, 56”, 59” and 60” wide liner

• Low profile liner cradle/uncoiler

• Multi-head pin spotter: choice of Duro Dyne® or Gripnail® - VICON Full Wrap Automatic Brake System

The VICON Full Wrap Automatic Brake System is a heavy duty high speed servo feed bending system.

• Heavy duty 5’ hydraulic bending unit with 16-26 gauge mild steel capacity

• System capable of L-section, U-section or full wrap duct (min. size for full wrap is 6” x 6” unlined), maximum capacity 120” wrap perimeter

• 48” and 60” duct lengths for slip & drive/ raw duct and 44” and 56” duct lengths for TDX duct

• Unit automatically controlled by VICON Control System

REQUEST A QUOTE FOR THIS MACHINE

Fill out the form and send it through to our team and we can help you get started with your inquiry.