The solution is called RAS XXL-Center!

The operator draws the profile of the multi-touch screen. The software automatically programs the part and suggests several folding strategies. The operator selects a folding sequence and the control simulates the entire program run in either a 2D or 3D view. After having starting the program, the load tables move out of the machine and the operator comfortably loads the sheet metal blank. An operator simply loads the workpiece and then unloads the folded part.

That’s it. The machine automatically inserts, squares, positions to the bend line, and folds the flanges up or down. No more rotation. No more complicated handling. No more second or third operator. The XXL-Center automatically produces precision long parts in record time!

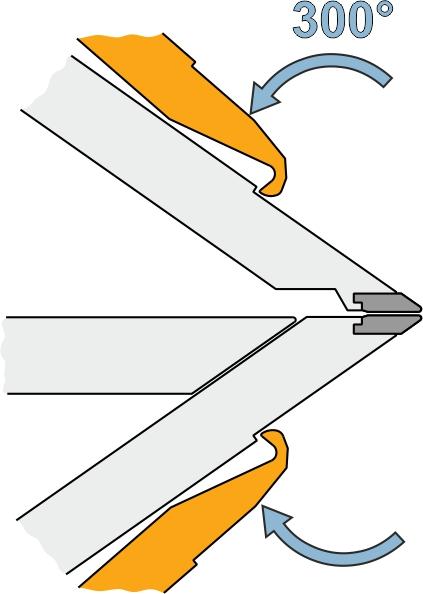

Because of the unique motion of the machine’s tools, it is possible to bend pre-coated sheets without scratching the material surface!

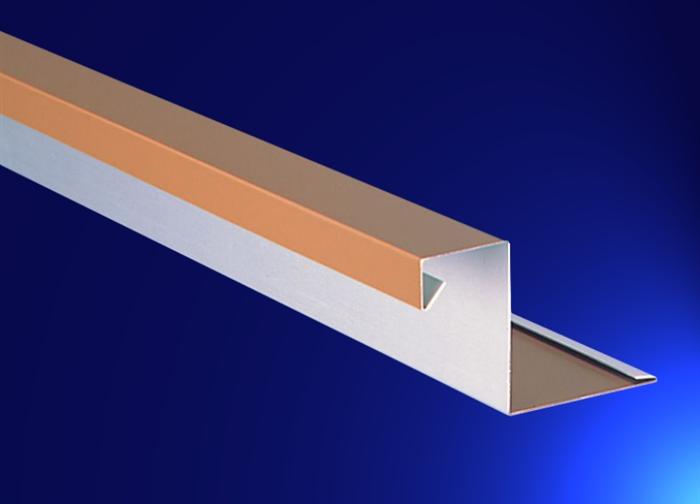

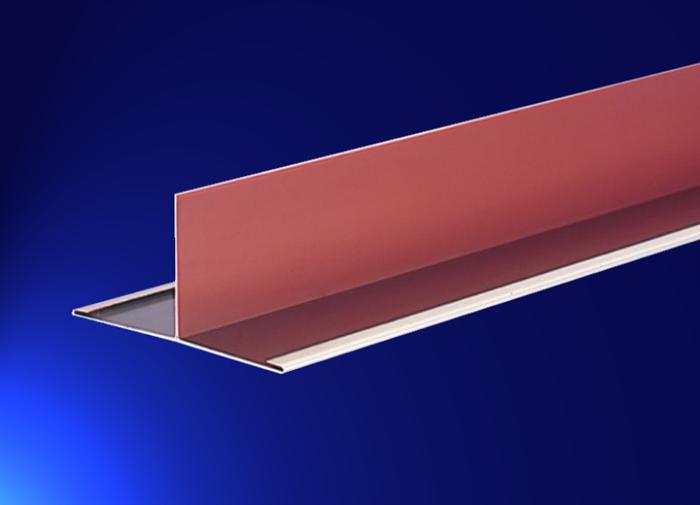

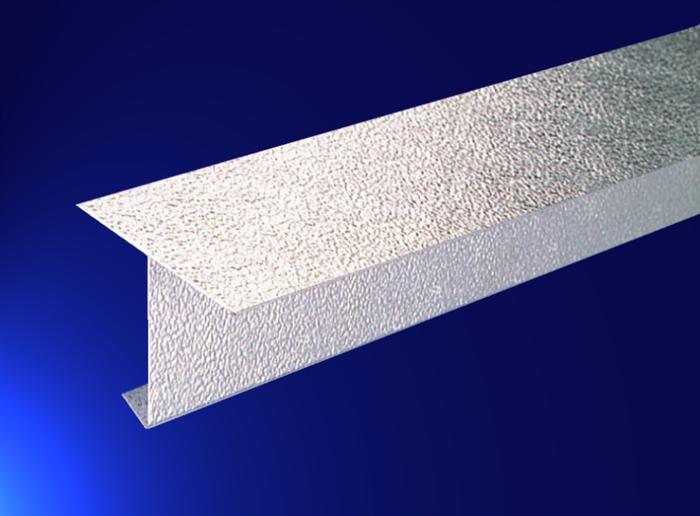

- Machine for roof & wall profiles

- Automatic inserting and positioning of blanks

- Bending up and down

- Scratch-free bending of sensitive materials

- Large free spaces for maximum part design flexibility

- Automatic bending sequences

- Automatic 1-click part programming

- High productivity

REQUEST A QUOTE FOR THIS MACHINE

Fill out the form and send it through to our team and we can help you get started with your inquiry.