DuctZipper-L: Designed for large ducts

On the DuctZipper-L the working position is rotated by 45 degrees. The horizontal flange of the duct rests on the table while the vertical flange directs straight up. Gripping groves in the vertical wall allow the operator an easy holding and guiding of the duct when passing through the machine.

Halved staffing needs

On the DuctZipper-L, it requires only two operators, who can handle even large 1500 x 1500 mm duct cross sections with ease. Smaller and medium-sized ducts can be completed with a single operator. The duct cross-sections can be pushed comfortably from the side into the machine and the seamed ducts can be also pulled out sideways without any effort. Then the finished duct will be simply tipped from the from stationary or moving table in the stable upright position. Benefitial addition effect: When hitting the floor the starting flanges of the seam will be automatically pushed into each other, thus ensuring an exact leading edge of the seam.

Operating speed doubled

Large ducts can be easily and quickly positioned in the DuctZipper-L. The sheet edges will be just inserted into the guide rail and clamped with the autopilot. There are no machine support components on the DuctZipper in L-shape that will pass through the machine and therefore the seaming process can start much quicker.

If the ducts are only medium size the second operator can already insert the following duct. After the first duct is finished and removed, the operator clamps the next duct with the AutoPilot and is ready to pass the next air duct through the machine.

Low load, high productivity

The horizontal loading and unloading of the ducts makes it completely superfluous heaving large and heavy duct cross-sections in and out of the machine. Instead, the workers can operate mostly in an upright posture, resulting in low back strain and a high and consistant productivity.

In the horizontal-vertical machine setup of the highest point of a 1500 x 1500 mm duct cross-section just protrudes 1500 mm beyond the rollers. The gripping height for the operator is reduced and the ducts will pass through the machine almost dimensionally stable.

Consistent long-term quality

The weight of the duct presses on the machine only to a small extent. The reduced load leads to low wear and a consistant long-term accuracy of the machine. The outout table of the machine supports the AutoPilot on a length of 2500 mm, so it is also possible passing extra long ducts safely through the L-shape DuctZipper. The horizontal table support is 200 mm wide. Beyond a variable width ailse a stationary or moving table can support the weight of the duct. In the vertical direction, the rear wall of the machine provides a support of the upraising flange up to 670 mm in height.

40-50% less space required

A horizontally positioned duct on DuctZipper in L-shape requires less space than a cross-section passing vertically through the machine. In the horizontal position, the flange length of the duct determines the space, while in the V-shape of the diagonal of the duct determines the floorspace requirement. In addition, on the L-shaped DuctZipper both operators are working from the same side of the machine. This allows in small workshops positioning the machine to a wall.

Improved seaming accuracy

As the U-shaped rail at the run-in side has been extended up to the forming rolls the duct will be guided to the very end. This improves the seaming quality on the DuctZipper in L-shape especially at the outlet side of the duct, which also results in a reduced distortion of the duct cross-section.

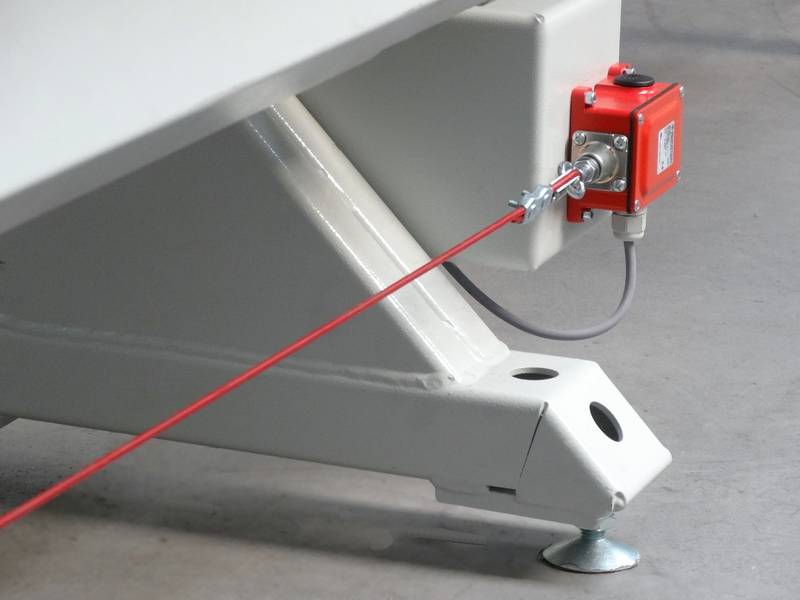

Increased safety

Even large ducts pass through the L-shape DuctZipper keeping their shape. As even large duct cross-sections do not tilt into one another, the DuctZipper-L impresses with an increased work safety. Should an unforeseen situation occur, an emergency shut-off cord along the machine frame increases operator safety.

Eased maintenance

As the orientation of the rolls is tilted by 45 degrees less zinc abrasion falls on the bearing points of the forming roll. For regular cleaning accessibility to the rolls is easy. Once on the front and back two screws were dissolved (safety rule), the metal cover on one side can be simply removed. On the other side it can be just tilted downwards.

Product Features

- Halved staffing needs

- Operating speed doubled

- Low load, high productivity

- Consistent long-term quality

- 40-50% less space required

- Improved seaming accuracy

- Increased safety

- Eased maintenance

REQUEST A QUOTE FOR THIS MACHINE

Fill out the form and send it through to our team and we can help you get started with your inquiry.