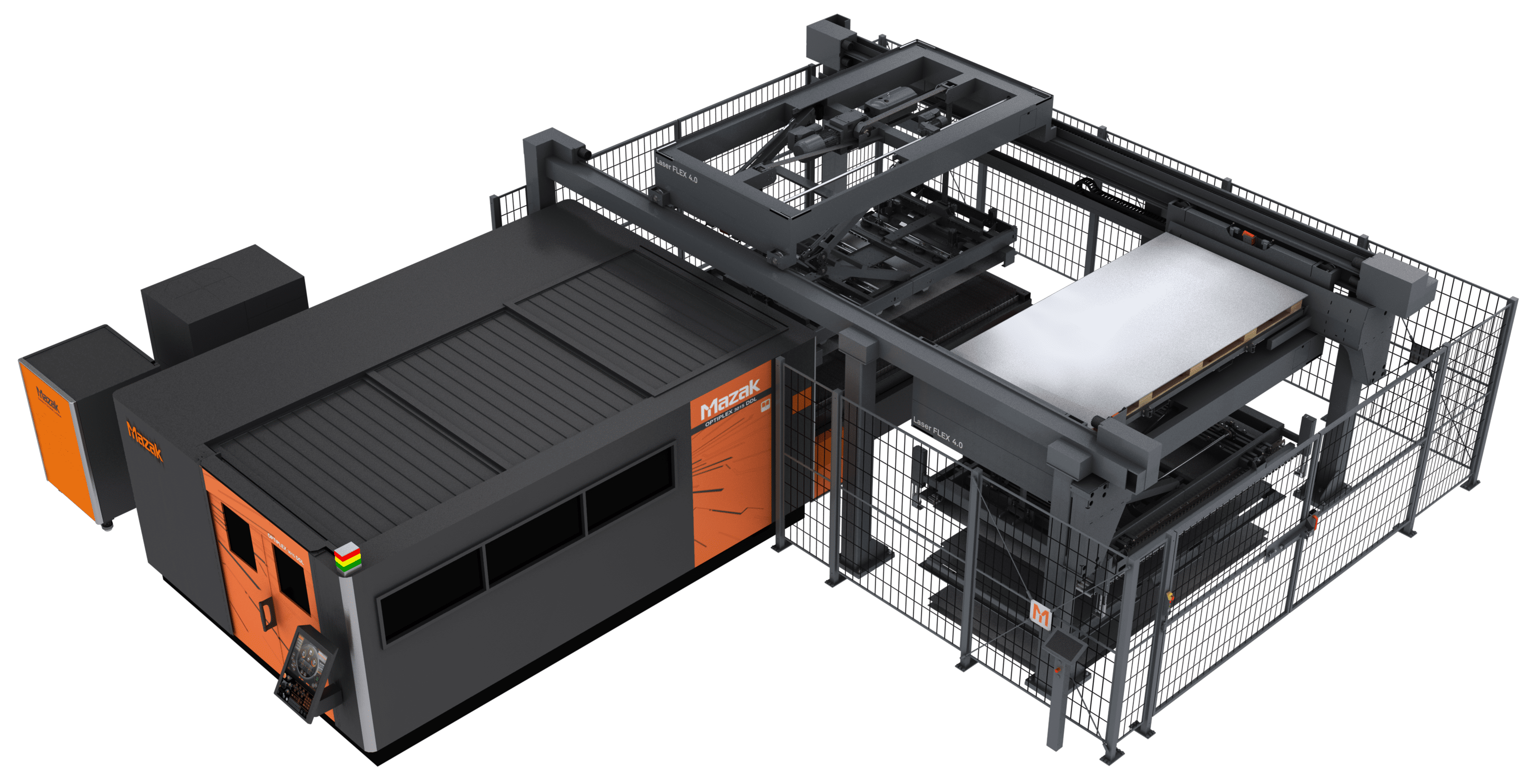

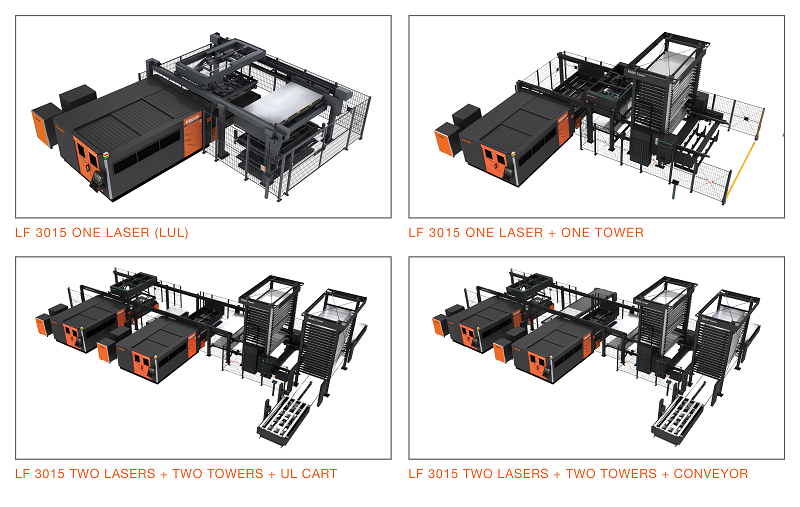

LASER FLEX systems utilize independent load/unload functions to accelerate sheet-to-sheet cutting productivity. Sheets are loaded utilizing a suction cup based system and unloaded by a clamshell fork system. The clamshell forks can optionally be ordered with a SOFT TOUCH belt system to reduce the possibility of scratching finished workpieces. Towers can be added for load/unload capacity while cart systems and conveyors allow workpiece separation as production continues.

LASER FLEX systems are available in a variety of 3015, 4020 and reverse flow configurations. They can be integrated into an automated storage/retrieval system for even greater capacity.

Mazak’s LASER FLEX automation can also be designed to incorporate systems to separate parts and automatically load them onto pallets in production environments.

REQUEST A QUOTE FOR THIS MACHINE

Fill out the form and send it through to our team and we can help you get started with your inquiry.