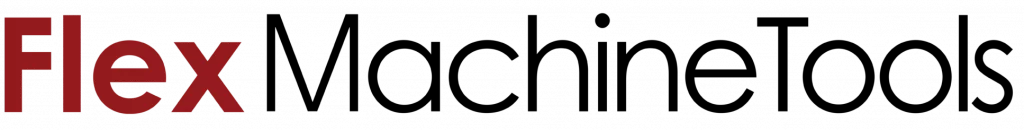

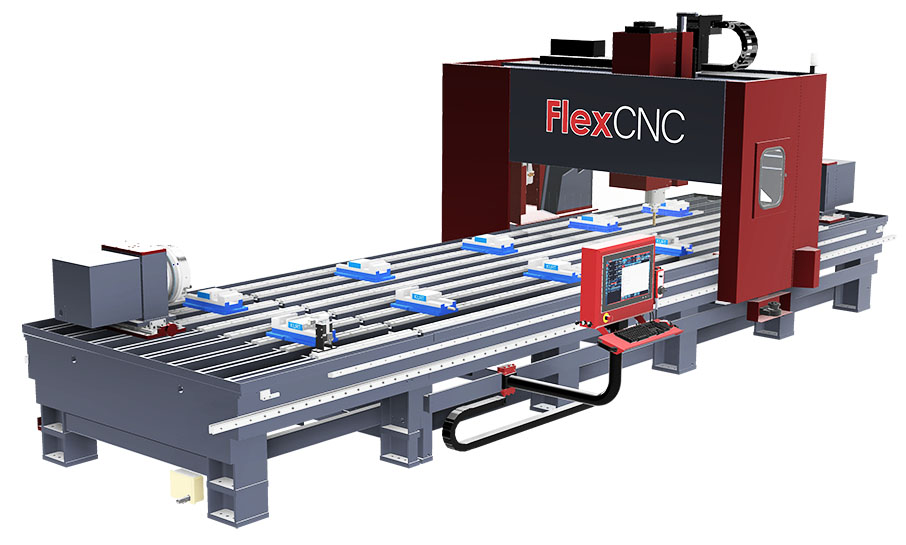

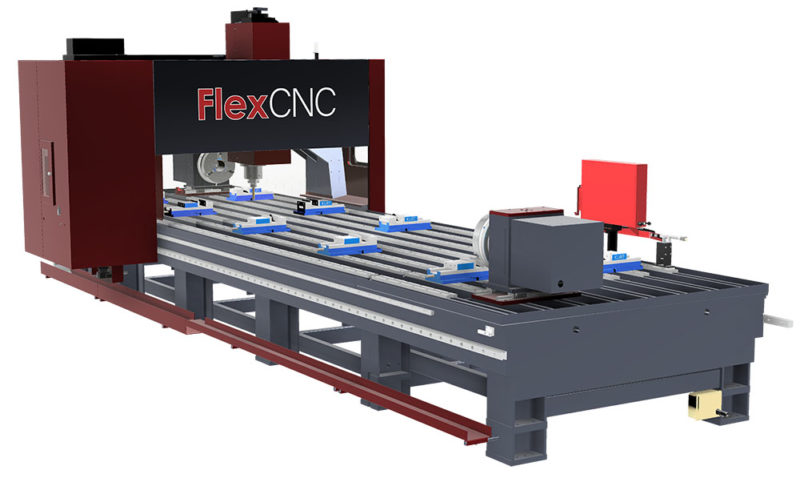

FLEX VERTICAL MACHINING CENTER

The FlexCNC is the best-priced and most flexible vertical machining center in the world. The FlexCNC G-Series is a gantry-style vertical machining center that ranges in size from 10’ to 80’ long. In addition to our standard sizes, we design and build custom machines to suit your needs.

Capable of high-speed drilling and milling of your large parts in one setup with less repositioning. It is available in four different spindle tapers; CT/BT40, CT/BT50, with a maximum peak torque capability of 220 ft/lbs. The G-Series features a monobloc, welded steel frame with high rigidity, a T-slot machine bed for easy fixturing, and a maximum torque of 230 ft/lbs. The machine is moved along two oversized precision linear guideways on each axis, and it includes a dual drive on the X-axis with a high precision helical rack and an oversized ball screw on the Y & Z-axis. Our motion control system is the most state-of-the-art CNC controller available, giving you the capability and Flexibility for your machining applications, large and small.

| X Stroke: | 10′ – 80′ |

| Y Stroke: | 4′ – 10′ |

| Z Stroke: | 20″ |

| Spindle to Table: | 5″ – 25″ |

| Rapid X: | Max 1500 IPM |

| Rapid Y: | Max 1500 IPM |

| Rapid Z: | Max 500 IPM |

Key features and specs

- Hand Pendant

- 22″ Touch Screen Monitor

- Omron FlexCNC Controller

- Mobile Control Panel

- Through Spindle Coolant

- Auto Tool Changer

- Flood Coolant

- Tool Calibrator

- LED Machine Light

- Ethernet Connection

- Safety Laser Scanner on Front of Machine

- Fence on the Rear of Machine

- 90 Gallon Coolant Tank

- Chip Auger & T-Slot Rails

Options

- Gearbox & ATC

- CT40 – ATC x 24

- Safety

- Light Curtain on Y-Axis

- Laser Scanner on Rear of Machine

- Convenience

- Z-Reader Probe

- Tool Break Detection

- Lubrication

- External Air Blast

- Through Spindle Air Blast

- External Micro Spray

- External Oil Spray

- External Paste Spray

- Through Spindle Micro Lube

- High Pressure Through Spindle Coolant 20 Bar

- 4th Axis

- 4th Axis with 10″ Platter, Adjustable Table and 3 Jaw Chuck (3D)

- 4th Axis with 16″ Platter, Adjustable Table and 3 Jaw Chuck (3D)

- Adjustable Manual Tailstock for 10″ Platter

- Fixturing

- Pneumatic Vise – Universal

- Pneumatic Vise – For Rounds 10″

- Pneumatic Vise – For Rounds 16″

- Pneumatic Vise – Multi

- Misc

- Bellow Covers for X & Y Axis

- A/C for Electrical Cabinet

- Chip Conveyor

REQUEST A QUOTE FOR THIS MACHINE

Fill out the form and send it through to our team and we can help you get started with your inquiry.