Professional air ducts!

Traditional methods rollform the receiver lock, than the rollform the flange, and finally connect the two and close the seam. The RAS DuctZipper does all this in one smooth and simple operation! The RAS material handling system supports the blanks and moves through the machine along with the duct work. After one seam is completed, the operator simply puts the duct crosswise onto the material guidance system and slides it back to the entry point. It’s that simple, easy and more often than not saves a second operator!

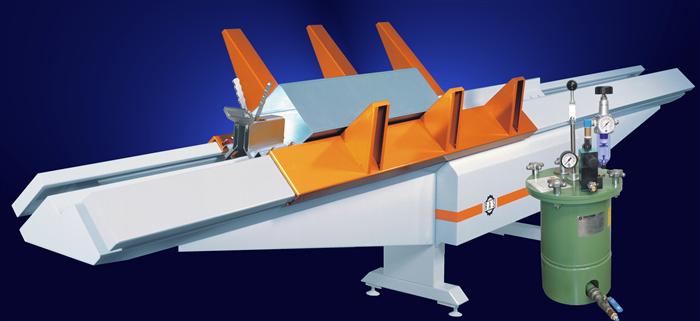

RAS SealJet

A vital factor in the air duct industry is the quality of the seam, which impacts the energy efficiency of the air duct. The RAS SealJet injection unit allows an easy, fast, efficient and clean seam joint sealing. The main elements are the RAS DuctZipper Duct Seaming Machine and the sealant Mez-Bluemastic gel. After the RAS DuctZipper has formed the seam, the SealJet injects an exact amount of the blue sealing gel in the base of the seam. Right after the injection, the DuctZipper forming rolls close the seam. Mez Bluemastic gel precisely seals the joint, preventing the sealing material from being squeezed out of the joint while closing the seam. After the process is completed, the sealant gel is not visible and both the air duct and the machine remain clean and mess-free.

REQUEST A QUOTE FOR THIS MACHINE

Fill out the form and send it through to our team and we can help you get started with your inquiry.