Seaming without Limits!

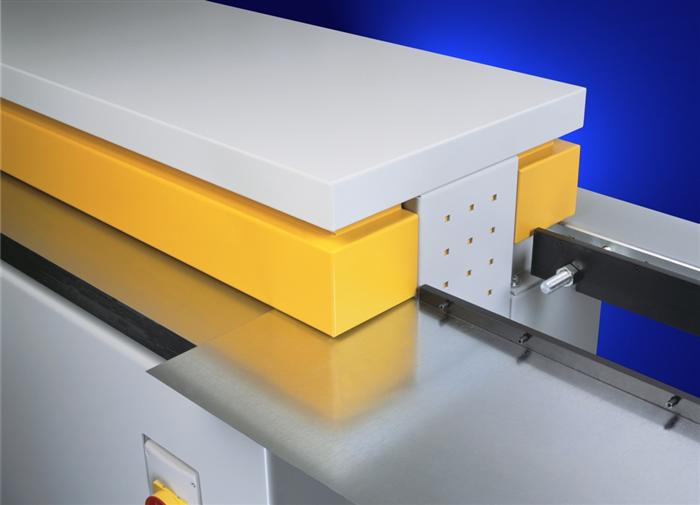

The machines can have two sets of rolls set up at a time. This allows to have a set of Pittsburgh Rolls on one side and a set of Standing Seam Rolls on the other side. The same could be done with a set of Snap Lock Rolls on one side and Cam Standing Rolls on the other. The rolls are made from the highest quality case-hardened special steel. For additional safety the sheet support tables can be adjusted to the different run heights of the right and left roller set.

Roller shafts, housed in axial and radial roller bearings, provide high-quality profiles. A wide gear box supports the roller shafts in the best possible way. The high-quality gear motor ensures smooth and quite running. It brings the drive power directly to rolls without transfer gears or belt drives in between.

The wear resistant and hardened entrance guiding system is not in contact with the usually plasma-cut material edges. Graved run-in sheet support tables thus belong to the past. Blanks stiffened with Z-seams can be processed easily, as the material guiding system uses downhold pins in the squaring arm. An optional leveling unit allows to straighten seamed blanks or round them for radius cheeks.

Ask for the RAS roller sets.Fragen Sie nach den RAS-Rollensätzen.

REQUEST A QUOTE FOR THIS MACHINE

Fill out the form and send it through to our team and we can help you get started with your inquiry.