Specialized on air ducts!

The application: Air ducts

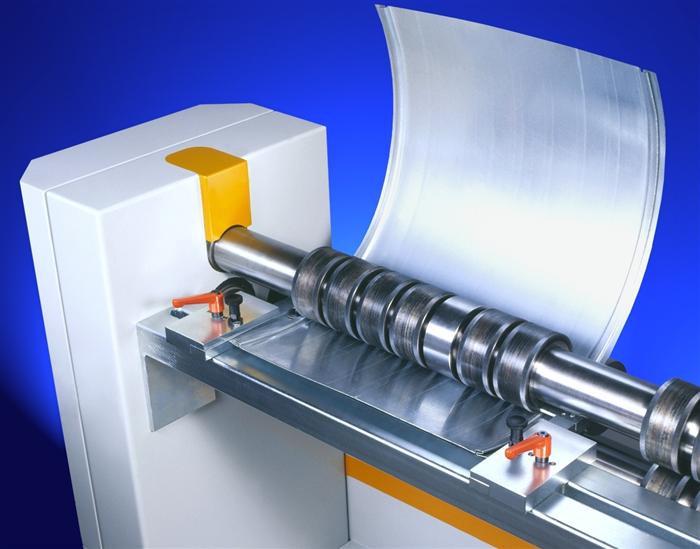

The RAS VENTIrounder for the air duct production solves all these problems. It easily rounds sheet metal elbow cheeks with pre-formed Snap Lock or Pittsburgh seams. The result are perfectly rounded inside and outside elbow cheeks.

The starting situation

The production elbow parts for air ducts starts with a rollforming process. This operation seams the blank and creates one part for the lock. This happens usually on a lockforming machine, for instance the RAS SpeedySeamer. In the second step the internal and outside elbow duct cheeks will be rounded on the requested radius.

Here a rounding machine comes into play. Traditional rounding machines use one part rolls. Since the part comes with the rollformed seam, traditional rounding machines can offer only some poor and costly compromises. Setting the rolls to the seam thickness results in poor radii. Stronger settings will damage the seam and in the long term also the rolls. Two remedies are known. Inserted metal strips, keep the seam open but must be manufactured separately and often can be used just once. Reusable mats must be produced also separately and need to be adjusted to the width of the elbow cheek.

The operation

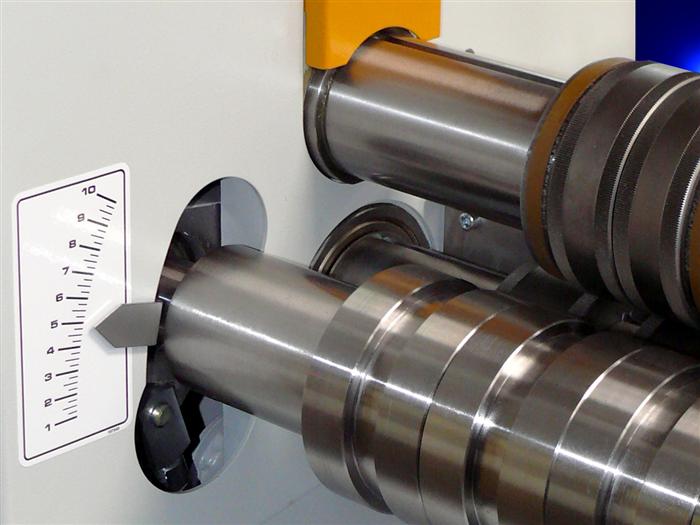

After having moved the rounding rings along the working length and set them to the approximate blank width, you can start rounding the blank. The rings round the sheet metal without touching the seams. Therefore the seams keep their geometry during the rounding process. A gear-brake motor with variable speed drives all three shafts and can be operated from a single phase outlet. The rear shaft can be set with a hand wheel for the adjustment of the bending radius.

REQUEST A QUOTE FOR THIS MACHINE

Fill out the form and send it through to our team and we can help you get started with your inquiry.